Research Lines

Aim of our research

The group PROCAT-VARES investigates on the field of Chemical Reaction Engineering targeting the sustainable development. The academic aim is to generate and transfer our knowledge in the form of publications, collaboration with industry and the training of researchers. The technological aims are: (1) the implementation of novel processes for the valorization of residues and wastes, (2) the production of fuels and chemicals from a sustained point of view, (3) intensification of the chemical processes already in use or in the development mode. These objectives are integrated within the concepts of biorefinery, sustainable refinery (waste-refinery), intensification and integration of chemical processes.

The group PROCAT-VARES has a broad experience in: (1) preparation and characterization of heterogeneous catalysts, (2) kinetic and thermodynamic studies of complex chemical processes, (3) design of chemical reactors (spouted bed, fixed bed, slurry, trickle bed, fluidized bed and with pneumatic transport), (4) hydrodynamic studies of spouted y trickle bed reactors, (5) studies of the mechanisms of catalytic deactivation and regeneration. The processes are studied from the nano-scale up to the pilot plant scale.

Line 1. Catalytic processes for fuels production by routes alternative to petroleum

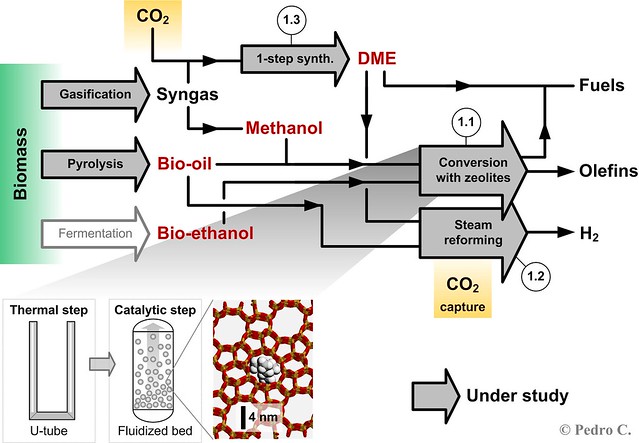

The sustainable refinery requires valorisation processes of petroleum alternative raw materials (coal, natural gas, waste materials), from renewable sources (vegetable biomass), aimed at obtaining petrochemical feedstocks and fuels.

1.1. Catalytic processes for oxygenates valorisation

We study various processes dealing with the transformation of oxygenates into gasoline or light olefins, based on (1) alternative catalysts, (2) innovative process conditions and (3) the design of new reactors. The transformation of methanol, bio-ethanol and bio-oil (product of the pyrolysis of biomass) is studied. Our results show an improved catalytic activity, selectivity and stability by optimizing the properties of the catalyst. We have also contributed to the understanding of the kinetics, thermodynamics, the bio-oil stability and its feed to the reactor, the deactivation and regeneration of catalysts. The design of the reactor for the catalytic conversion of bio-oil has been improved with the proposal of a two-step system: thermal, for the controlled deposition of pyrolytic lignin, and catalytic.

Valle, B.; Gayubo, A. G.; Alonso, A.; Aguayo, A. T.; Bilbao, J., Hydrothermally stable HZSM-5 zeolite catalysts for the transformation of crude bio-oil into hydrocarbons. Appl. Catal. B: Environ. 2010, 100 (1-2) 318-327. doi: 10.1016/j.apcatb.2010.08.008

1.2. Hydrogen production by reforming of oxygenates

We study the catalytic steam reforming of oxygenates for the production of hydrogen, feeding bio-ethanol, dimethyl ether or bio-oil. The

Vicente, J.; Remiro, A.; Atutxa, A.; Erena, J.; Gayubo, A. G.; Bilbao, J., In situ capture of CO2 in the steam reforming of ethanol over Ni/SiO2 catalyst for hydrogen production. Chem. Eng. Transaction 2009, 17, 1567-1572. doi: 10.3303/cet0917262

1.3. Synthesis of dimethyl ether in one reaction step

The dimethyl ether (DME) is a "platform chemical" for the synthesis of various chemical compounds of interest, as well as an excellent additive to diesel. The synthesis of DME is made from raw materials alternatives to petroleum, such as coal, natural gas or biomass. Our effort focuses on the study of: (1) different feeds of H2/CO/CO2, (2) complex kinetic models, (3) study of the deactivation and regeneration of catalysts, (4) new bifunctional catalysts, (5) innovative design of reactor to overcome thermodynamic barriers (with membranes or temperature profiles within the reactor).

Sierra, I.; Erena, J.; Aguayo, A. T.; Arandes, J. M.; Olazar, M.; Bilbao, J., Co-feeding water to attenuate deactivation of the catalyst metallic function (CuO-ZnO-Al2O3) by coke in the direct synthesis of dimethyl ether. Appl. Catal. B: Environ. 2011, 106 (1-2) 167-173. doi: 10.1016/j.apcatb.2011.05.021

Line 2. Intensification and integration of refinery catalytic processes

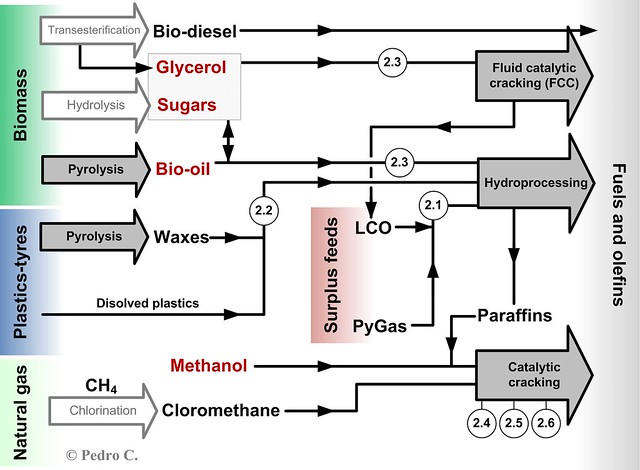

Refineries have to deal with new challenges to upgrade waste, residues, or streams of secondary interest. The adaptation of these feeds into fuels falls to the following conversion units: (1) fluid catalytic cracking (FCC) and (2) hydrocracking. In addition, new possibilities are opened for the upgrading and intensification of these materials that the PROCAT-VARES group is studying.

2.1. Upgrading of aromatics by hydrocracking

Aromatics production in refineries exceeds the projected demand. As such, aromatics transformation into alkanes is being studied by our PROCAT-VARES group. These alkanes are converted into olefins through steam cracking. The necessary hydrogen is obtained from the same unit of steam cracking. Another strategy under study is the upgrading of highly aromatic streams (residuals), such as light cycle oil (LCO) via hydrocracking, in order to produce high added value fuels. The knowledge of the bifunctional catalyst properties regarding product distribution and deactivation has been improved. Moreover, kinetic models of the hydrocracking processes have been developed in parallel.

Castano, P.; Gutierrez, A.; Villanueva, I.; Pawelec, B.; Bilbao, J.; Arandes, J. M., Effect of the support acidity on the aromatic ring-opening of pyrolysis gasoline over Pt/HZSM-5 catalysts. Catal. Today 2009, 143 (1-2) 115-119. doi: 10.1016/j.cattod.2008.10.029

2.2. Upgrading of plastic wastes by hydroprocessing

Plastic wastes are a pressing problem in our society. Various strategies regarding the upgrading of plastics are being studied within our PROCAT-VARES group. Amongst those studied, this section deals with the hydroprocessing (hydrogenation, hydrotreatment, or hydrocracking) of waste plastics: (1) polyolefins (polyethylene and polypropylene) dissolved in other secondary refinery streams or (2) waxes and liquids produced in the pyrolysis of tyres, polyolefins, or other plastics. In this manner, fuels with excellent properties for being incorporated into current refinery schemes are produced.

2.3. Cracking and hydrocracking of oxygenates

The cracking and hydrocracking (as alternatives) of glycerol and carbohydrates, subproducts of the production of biodiesel and agricultural surplus. The upgrading of these renewable streams is a challenge of maximum relevancy nowadays due to the volume of both. In parallel fashion, the hydrocracking-hydrodeoxygenation of bio-oil has begun to be studied.

Nava, R.; Pawelec, B.; Castaño, P.; Alvarez-Galvan, M. C.; Loricera, C. V.; Fierro, J. L. G., Upgrading of bio-liquids on different mesoporous silica-supported CoMo catalysts. Appl. Catal. B: Environ. 2009, 92 (1-2) 154-167. doi: 10.1016/j.apcatb.2009.07.014

2.4. Obtaining olefins by the combined cracking of paraffins and methano

The steps of the combined paraffin and methanol catalytic cracking process are being studied in order to selectively obtain C2-C4 olefins. The combined transformation offers energetic compensation advantages across both reactions. Different process levels are studied: (1) regarding the catalyst, catalysts with different shape selectivity, different treatments, and different acidity levels are studied; (2) in regards to operation conditions, the methanol/paraffin ratio and the effects of the N2 and of the steam are studied. Our knowledge of the reactions mechanism, the deactivation mechanism, and that of the complete kinetic process has been advanced.

Aguayo, A. T.; Castano, P.; Mier, D.; Gayubo, A. G.; Olazar, M.; Bilbao, J., Effect of Cofeeding Butane with Methanol on the Deactivation by Coke of a HZSM-5 Zeolite Catalyst. Ind. Eng. Chem. Res. 2011, 50 (17) 9980-9988. doi: 10.1021/ie200946n

2.5. Obtaining of olefins from methane via chloromethane

Light olefins are obtained from methane, via chloromethane, maximising the yield of propylene. This strategy allows for incorporating methane (from the natural gas) as a raw refinery material. Methane is a secondary product from various refinery units and its reserves are growing due to the new extraction techniques of natural gas. Improved catalysts and kinetic models are being studied so as to an increase propylene selectivity.

2.6. Intensification in obtaining propylen

The conversion of butenes and alkanes into propylene is being studied. The aim is to compensate for the imbalanced production of olefins in respect to market requirements: with a higher demand for propylene. The research is focused on the catalyst, the kinetic model, and the reactor design.

Mier, D.; Aguayo, A. T.; Gamero, M.; Gayubo, A. G.; Bilbao, J., Kinetic modeling of n-butane cracking on HZSM-5 zeolite catalyst. Ind. Eng. Chem. Res. 2010, 49 (18) 8415-8423. doi: 10.1021/ie1006245

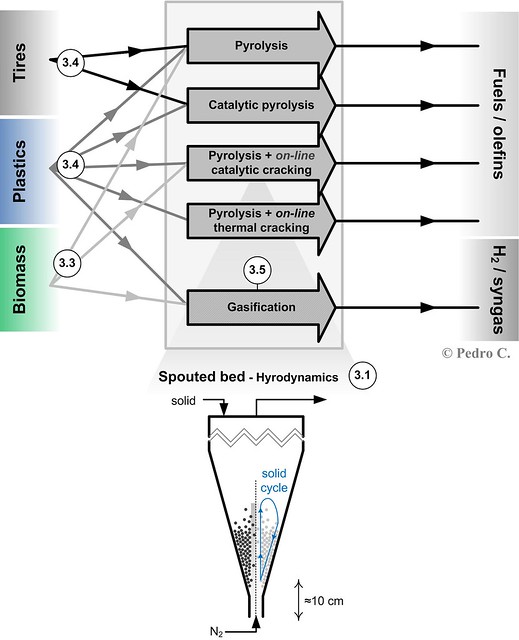

Line 3. Design and applications of Spouted Beds: Upgrading by combustion, pyrolysis and gasification of biomass, plastics and tires

Spouted bed reactors represent an alternative gas-solid contact method to fluidised beds. Due to the solid cyclic movement, spouted beds are especially adequate for handling materials that are irregular, with a wide size distribution, of different densities and even of sticky nature. Conical spouted bed reactor has been successfully applied to pyrolysis (thermal and catalytic) and gasification processes of different solid wastes such as biomass, plastics and tires.

3.1. Design and hydrodynamics of spouted beds

We are studding the effect of the geometric factors and different types of internal devices (porous, non-porous and open-sided) on the hydrodynamics. The main objectives are: the improvement of bed stability, gas distribution and solid circulation. Development of conical spouted bed technology for the dying of granular materials.

Altzibar, H.; Lopez, G.; Aguado, R.; Alvarez, S.; San Jose, M. J.; Olazar, M., Hydrodynamics of conical spouted beds using different types of internal devices. Chem. Eng. Technol. 2009, 32 (3) 463-469. doi: 10.1002/ceat.200800605

3.2. Combustion of wood and other biomass residues

The Group has the spouted bed combustion technology patented. Currently we are developing projects for the industrial application of this technology.

Olazar, M.; San Jose, M.J.; Bilbao, J.; Dispositivo para la combustion en continuo de residuos solidos. (2001) 2148026-9700662. Explotada por NAPOWER, S.L. y RESTOLVI, S.L

3.3. Biomass pyrolysis and on line catalytic cracking

Continuous pyrolysis of different types of biomass such as pinewood sawdust, rice husk, eucalyptus wood and bark etc. Development of strategies for the scale up of the process: Vacuum and autothermal pyrolysis. Two step process: Pyrolysis and on-line catalytic reforming for the upgrading of bio-oil and production of high added value products.

Amutio, M.; Lopez, G.; Aguado, R.; Artetxe, M.; Bilbao, J.; Olazar, M., Effect of vacuum on lignocellulosic biomass flash pyrolysis in a conical spouted bed reactor. Energy Fuels 2011, 25 (9) 3950-3960. doi: 10.1021/ef200712h

3.4. Thermal and catalytic pyrolysis of plastics and tires

Pyrolysis of polyolefins (HDPE, LDPE and PP), polystyrene, Poly-(ethylene terephthalate) and poly-(methylmethacrylate). In situ and on-line catalytic pyrolysis of polyolefins. Pyrolysis and high temperature cracking of polyolefins. Thermal and catalytic pyrolysis of tires, vacuum pyrolysis.

Lopez, G.; Olazar, M.; Aguado, R.; Elordi, G.; Amutio, M.; Artetxe, M.; Bilbao, J., Vacuum pyrolysis of waste tires by continuously feeding into a conical spouted bed reactor. Ind. Eng. Chem. Res. 2010, 49 (19) 8990-8997. doi: 10.1021/ie1000604

3.5. Steam gasification of plastics and biomass

We are studding the production of syn-gas and hydrogen by steam gasification. This has been performed in two step process: (1) Steam gasification and (2) reforming by using a nickel catalyst. Optimization of the gasification by means of in situ catalysis.

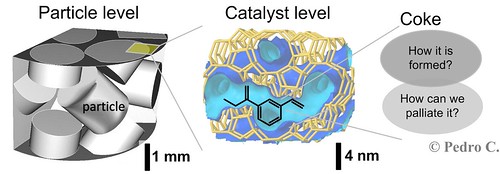

Line 4. Deactivation of acid and bifunctional catalysts

In all the valorization and transformation processes concerning oxygenates, wastes and residual feeds, the catalysts used show a severe deactivation. The origin of this deactivation is mainly the deposition of hydrocarbons with lower ratio of H/C than that of the feed; what is known as coke. We are investigating the mechanisms and the pathways of this deactivation, and suggesting strategies that enable to maximize the life of the catalyst and the viability of each of the processes.

Castano, P.; Elordi, G.; Olazar, M.; Aguayo, A. T.; Pawelec, B.; Bilbao, J., Insights into the coke deposited on HZSM-5, Hbeta and HY zeolites during the cracking of polyethylene. Appl. Catal. B: Environ. 2011, 104 (1-2) 91-100. doi: 10.1016/j.apcatb.2011.02.024