It is common practice to add different types of fibres to mortar or concrete to render it more durable, tougher and firmer. To avoid having to manufacture these additives, a researcher in the UPV/EHU’s Department of Mechanical Engineering, together with the Bio-Bio and Andres Bello universities in Chile, has resorted to industrial steel waste in the form of fibres and shavings, and determined how they change the properties of the resulting compound, depending on the quantities added.

-

In memoriam: Arturo Muga

-

Violeta Pérez Manzano: «Nire ahotsa ijito bakar batengana iristen bada eta horrek inspiratzen badu, helburua bete dut»

-

In memoriam: German Gazteluiturri Fernández

-

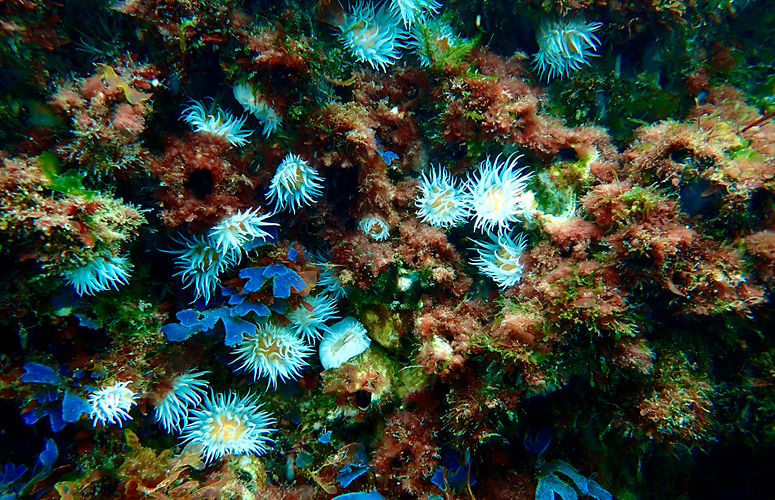

Itsasoaren gainazalaren tenperatura-igoerak aldaketa sakonak eragin ditu makroalgen komunitateetan

-

Azukrea eta edulkoratzaileak. Zer jakin behar dut?

Mortar reinforced with industrial steel waste is long-lasting but cannot be monitored

The UPV/EHU-University of the Basque Country and two Chilean universities determine the properties acquired by mortar containing waste comprising steel fibres and shavings

- Research

First publication date: 16/07/2018

Right now, there is a huge variety of mortars on the market that have plastic, carbon and metallic fibres etc. incorporated into them to reinforce them. “In our research, we wanted to use fibres that have not been through a manufacturing process and we resorted to steel waste in the form of fibres and shavings generated in the industry. That way, we managed firstly to avoid actually having to manufacture the fibres and, secondly, to reuse the industrial waste directly without subjecting it to any recycling process,” said Roque Borinaga-Treviño, a researcher in the UPV/EHU’s Department of Mechanical Engineering and one of the authors of this work.

In the research they also wanted to check whether there was any possibility of monitoring the structures reinforced with steel waste. In previous studies, it was possible to demonstrate that the monitoring of electrical and thermal properties allows cracks in the structures for example to be detected. “Should a crack appear, there would be a disconnection between the fibres which would modify the electrical and thermal properties of the mortar. So in the measurements made using various devices we would detect some bigger differences,” explained Dr Borinaga.

The study involved monitoring the way in which the electrical and thermal properties change depending on the type and quantity of waste used. For the part relating to the electrical properties, they took the monitoring of the electrical resistivity of the mortar as the indicator. Mortar is characterised by having great electrical resistivity, in other words, the capacity of electricity to pass through it is very limited. Fibres, however, lower this resistivity. With respect to thermal properties, the chosen indicator was thermal conductivity. The thermal conductivity of steel is between 15 and 20 times higher than that of mortar, so a conventional mortar would display greater resistance to heat passing through it than one reinforced by steel fibres.

Swings and roundabouts

The results obtained “are not entirely significant,” said Borinaga. They were able to see that the metallic waste used, irrespective of the type and quantity, does not significantly alter either the electrical resistivity of the mortar or its thermal conductivity. Therefore, “they are not considered to be appropriate for monitoring with the indicators we presented, as we would not notice any difference between the normal and the reinforced mortar,” explained the researcher.

Yet the fact of having available the steel waste reinforcement "exerted no negative effect on the quality of the mortar,” pointed out Dr Borinaga. “And mortar that contains fibres is known to generally last longer. So it is possible to assert that the mechanical properties of the mortar are improved.”

As regards the issue of monitoring, Borinaga explained that they would be continuing with the research: “We may change the design of the mortar or try with other quantities and types of waste, or we may try to conduct the monitoring using other techniques such as ultrasound or induction.”

Additional information

This research was the outcome of collaboration between three universities. Roque Borinaga-Treviño, the researcher in the UPV/EHU’s Department of Mechanical Engineering, specialises in the thermal and mechanical analysis of mortar, while the collaborators at the Bio-Bio University work on adding asphalt fibres. They brought together their areas of knowledge in order to conduct the experiments on mortar, and the Andrés Bello University collaborated in making available the means and in the analyses.

Bibliographic reference

- Electrical and thermal characterisation of cement-based mortars containing recycled metallic waste

- Journal of Cleaner Production

- DOI: 10.1016/j.jclepro.2018.04.176