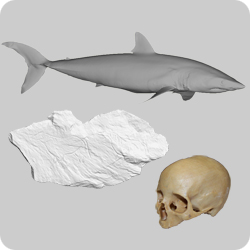

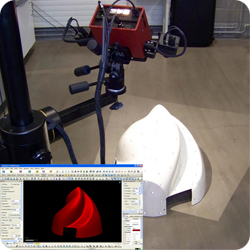

In the laboratory, we work with small and medium-size pieces, and with a resolution below 0.03 mm. The scanning equipment is portable. The purpose of the Reverse Engineering process can go from a simple digitization to a parametric redesign of the part or to a inspection of the manufactured part. |