A piece of research by the Materials+Technologies group of the Department of Chemical Engineering and the Environment and the Department of Cell Biology and Histology, both of the UPV/EHU, has produced a material comprising polyurethane and cellulose with water-activated, shape-memory properties, and which is suitable for applications in biomedicine, among other things. Furthermore, the cellulose has been obtained by means of bacterial biosynthesis using cider production waste as a source of food for the microorganisms.

A shape-memory material consisting of polyurethane and bacterial cellulose is created

A group at the UPV/EHU-University of the Basque Country has optimised the biosynthesis process of bacterial cellulose by using the residues of cider production as food

- Research

First publication date: 25/06/2019

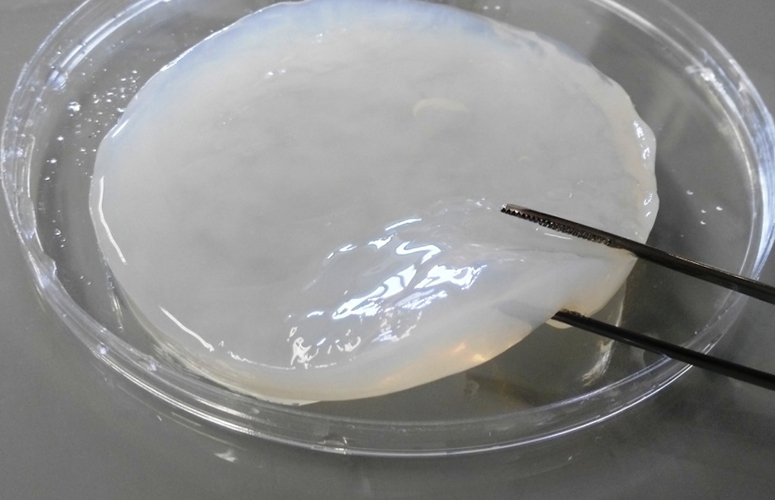

The journal Carbohydrate Polymers has recently published a piece of research work conducted between the Materials+Technologies research group of the Department of Chemical Engineering and Environment of the Faculty of Engineering - Gipuzkoa and the Department of Cell Biology and Histology of the Faculty of Medicine and Dentistry, both belonging the UPV/EHU. The outcome of this work was a hybrid, biocompatible material with shape-memory properties, in other words, “with the capability of recovering its original shape when an external stimulus (in this case, water) is applied after the material has been temporarily deformed”, explained Leire Urbina, member of the Materials+Technologies research group and lead author of the paper.

This quality makes the material highly suited to “biomedical applications, such as the controlled release of drugs, tissue engineering, etc. The deformed, folded material could be inserted into the body and that way minimally invasive surgery would be required. After coming into contact with the moisture in the organism, it would activate and recover its original shape and thus be able to perform its function”, pointed out the researcher.

The compound material has two components. The first is the polyurethane, a thermoplastic polymer, “which has shape memory and which over the last few years has gained huge importance in studies of this type”, she said. But Dr Urbina highlighted the use of the second component, the bacterial cellulose: “We used a tiny percentage of cellulose, less than 2%, but this amount of cellulose improved the properties of the final material considerably: the cellulose produces a more rigid, more resistant material and, what is more, significantly improves its capability of returning to its original shape, because we saw that the polyurethane on its own does not recover its shape fully.”

The biocompatibility studies also produced good results, which renders this material flexible, transparent and with enhanced mechanical properties with the potential for use in the field of biomedicine, although Dr Urbina pointed out that what they have done has been the first step, “to confirm that it is a non-cytotoxic material and that cells adhere to it well. The work will be completed with other specific tests for application purposes such as in vivo tests”.

Cellulose excreted by bacteria fed on cider residues

The biosynthesis process of the cellulose used occupied a significant part of the research. “For many years our research group has been working with bacterial cellulose, which is a biopolymer produced by bacteria mainly of the Acetobacter genus,” said Urbina. “During the biosynthesis process, each microorganism excretes cellulose nanofibres into the culture medium through pores they have in the cell membrane and the latter combine to form a kind of 3D network structure. This conformation provides the bacterial cellulose with properties that stand out over plant-based cellulose, such has high mechanical resistance, greater crystallinity and purity, a high water-retention and chemical modification capacity, biodegradability, biocompatibility, and even the capacity for moulding in accordance with the shape one wants to achieve, given that it is possible to make the bacteria grow in containers of the desired shape.”

“Cider production residues” were used as a source of food for bacterial growth. “The by-products of the cider process (pulp, cake, dregs, etc.) are rich in sugars (glucose, fructose and saccharose) and therefore can be used as a fermentation medium for the bacteria. In cider production, approximately 30% of the apples used is left as a residue, so its use as a source of carbon for bacterial growth constitutes an upgrading of the waste to obtain high, added-value materials,” stressed the researcher.

This measure addresses one of the greatest challenges facing the technology of bacterial polymers which is to find suitable, cost-effective sources of carbon that can be used as substrates to achieve large-scale industrial production and which can compete with petroleum-based polymers.

Additional information

This work is part of the PhD thesis by Leire Urbina, entitled Biosynthesis and characterization of polymers from cider by-products. Bacterial cellulose-based nanocomposites, supervised by Dr Aloña Retegi and Dr Mª Angeles Corcuera, and written up in the UPV/EHU’s Materials+Technologies Group of the Department of Chemical Engineering and Environment of the Faculty of Engineering - Gipuzkoa. This group has been working on the development of multifunctional (bio)materials by applying knowledge from biotechnology and nanotechnology, and collaborates with various research groups both at the UPV/EHU, and also in Spain and abroad.

Bibliographic reference

- Hybrid and biocompatible cellulose/polyurethane nanocomposites with water-activated shape memory properties

- Carbohydrate Polymers (2019)

- DOI: 10.1016/j.carbpol.2019.04.010