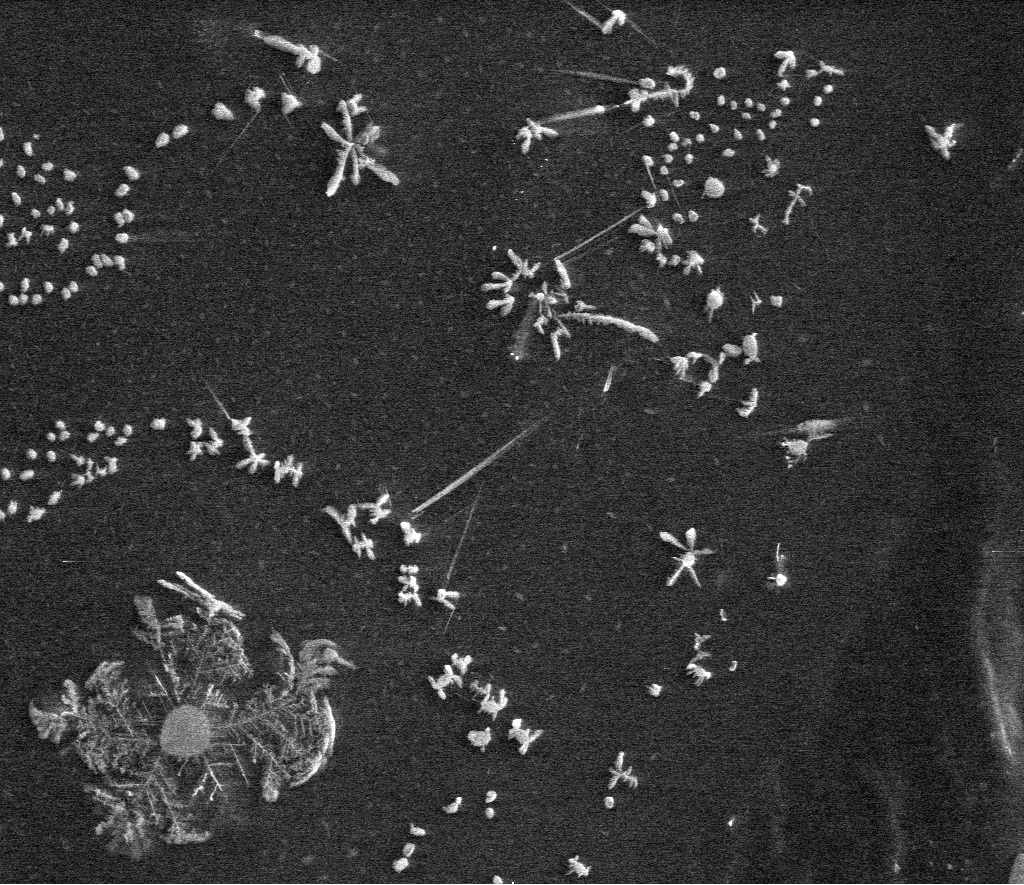

Cross section SEM micrograph of a continuous carbon fiber (CCF) filament is shown in the figure above. This filament consist of multiple continuous carbon fibers embedded in a thermoplastic matrix (polycarbonate). The filament has an average diameter of 1.75mm and has approximately 24,000 carbon fibers with an individual diameter of 7μm. As it can be observed, the carbon fibers are uniformly distributed in the center of the polycarbonate matrix, and a large central fiber-rich region is clearly distinguishable. In areas without matrix where fibers remain unimpregnated, small voids could be seen, resulting in a weaker surface bond between fibers and thermoplastic. These defects can be attributed to the high melt viscosity of the polycarbonate, which complicates the mobility of the polymer chains during fiber fabrication by coextrusion.

The function of this coating is exclusively that of a vehicle to be able to 3D print the reinforcement fibers. Filament extrusion was performed In a Brabender Plasticorder PLE-650 extruder machine with a screw aspect ratio L/D = 25 and with a coaxial extrusion mold, while filament winding was performed by a strand pelletizer adapted for non pelletizing. The procedure of the extrusion starts with the CCF spooled on a winding and fed into the coaxial extrusion mold, while the thermoplastic pellet that will act as the thermoplastic coating is fed into the extruder. The molten thermoplastic is compressed around the fiber in the nozzle. After coating, the CCF filament is cooled in a water bath to solidify. Finally, the strand pelletizer pulls the strand and keeps the processing speed constant.